Oberflex est spécialisée dans la fabrication et la commercialisation de surfaces décoratives et de solutions acoustiques pour l’agencement intérieur. L’entreprise propose de nombreuses collections à base de bois, papier, métal, résine, adaptées à tous types de projets (tertiaire, hôtellerie-restauration, commerces, bâtiments publics ou résidentiels). Entreprise du Patrimoine Vivant (EPV), Oberflex met son savoir-faire au service de l’innovation pour constamment proposer de nouvelles solutions techniques et esthétiques.

À la une

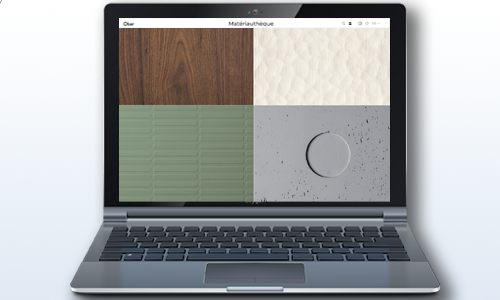

La Matériauthèque en ligne

Bois, béton, métal, couleurs, ... en 3 clics, sélectionnez et combinez des produits d'agencement adaptés à votre projet. Créez, sauvegardez et partagez vos planches de matériaux.

Micro-rainures Obersound®

Une série de panneaux acoustiques dont la multitude de rainures microscopiques leur confère une absorption exceptionnelle.

Le journal des nouveautés

Bienvenue dans le journal des nouveautés d’Oberflex, où l'innovation est à portée de main et où esthétique et qualité sont une norme.

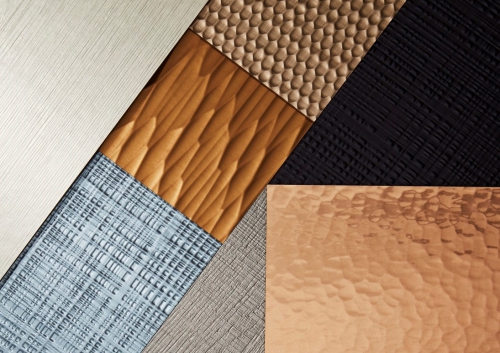

Nouvelles textures 3D sur métal

Six nouvelles textures emblématiques déclinées sur les finitions alu, inox, bronze, cuivre, laiton, étain, à la façon d'une sculpture métallisée digne d'un travail artisanal minutieux.

Jouez la matière avec Oberflex et Concrete LCDA

Oberflex et Concrete LCDA offrent un vaste choix de surfaces décoratives et de solutions techniques pour l’agencement intérieur.

Color anti-fingerprint

Nouvelle finition anti-trace de doigt.

Oberflex, lauréat du CSI award 2023

Le 5 décembre dernier à Londres, Oberflex devient lauréat du prestigieux Prix de l'Innovation du Cruise Ship Interior show et renforce ainsi son rôle d'acteur clé sur le marché des navires de croisières.

Small Spaces in the City

Une exposition qui nous fait réfléchir sur l'agencement des petits espaces de vie et de travail en milieu urbain, avec la participation d'Oberflex.

Une fabrication 100 % française

Oberflex conçoit et fabrique dans l'Est de la France sur son site originel depuis 1925.

SuperOrganic by Oberflex

Des surfaces décoratives 100% naturelles composées de matières végétales (foin alpin, pétales de fleurs, paille de bois...) et disposées sur une toile de lin. Une véritable expérience sensorielle !

Basic by Oberflex

Basic by Oberflex, une solution bois économique pour vos projets d’envergure.

Nous venons à votre rencontre

A vos agendas : Oberflex expose et vous invite à découvrir ses dernières innovations sur les meilleurs salons professionnels.

August Debouzy change de peau

Changement d'adresse et de décor pour August Debouzy. Les panneaux Oberflex en Orme d'Amérique mis à l'honneur.

Panneaux acoustiques Obersound

Pour améliorer le confort acoustique d'un espace intérieur. Invisibles ou au contraire très graphiques pour un effet décoratif pleinement assumé, découvrir les différents modèles de perforations...

A propos de Marotte

Plus de 70 ans consacrés à l’agencement intérieur et à l’ébénisterie haut de gamme en offrant un choix exceptionnel de produits de qualité.

Oberflex Entreprise du Patrimoine Vivant - EPV

Ces trois lettres sont le signe distinctif des entreprises qui font vivre les savoir-faire et perpétuent une exigence de qualité.

La Matériauthèque Ober s'installe à Paris

Architectes, designers ou étudiants peuvent désormais découvrir dans un lieu riche et créatif l'ensemble des collections proposées par Oberflex et Concrete LCDA. Une occasion idéale pour explorer grandeur nature la variété, les reliefs et les textures de chaque collection.

Configurez votre propre panneau acoustique

Un nouvel outil pour explorer l'ensemble des solutions acoustiques Obersound

Trophées de l'Innovation 2021

Les revêtements muraux SuperOrganic ont été reconnus comme étant la solution d'aménagement résolument innovante, belle et saine en tous points de vue.

Système de plafonds suspendus "Tectonique 5.5"

Une nouvelle collection de plafonds suspendus prêts à poser. Tectonique 5.5 permet de créer des rythmes nouveaux et des plafonds en 3D à partir d’un système de fixation inédit et standardisé.

La collection "Prestige d'Oberflex" s'enrichit

Des nouvelles références et un retour aux grands classiques

Shelter créateur lunetier

Cette jeune marque de lunettes en bois, créative et vertueuse, s'appuie sur le savoir-faire Marotte pour produire des lunettes de grande qualité.

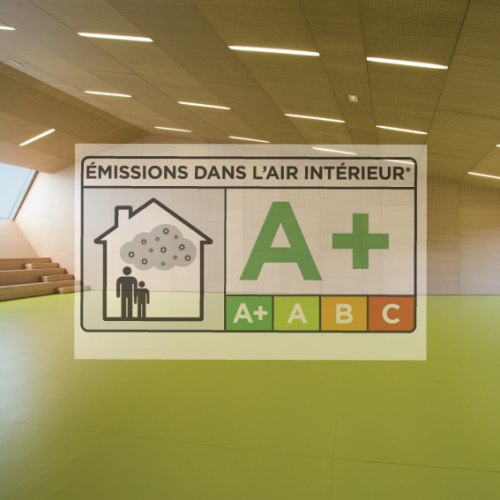

Les panneaux Oberflex classés A+ pour la qualité de l'air intérieur

Nous passons en moyenne 85% de notre temps dans des environnements clos, la qualité de l'air intérieur est donc devenue une préoccupation sanitaire majeure.

Le stratifié qu'est-ce que c'est ?

Le métier du stratifié, sa fabrication, sa mise en oeuvre, par le journaliste Christophe Lahaye

Améliorer le confort acoustique d'un espace intérieur

Consiste à définir des objectifs en terme de caractéristiques acoustiques en tenant compte de l'usage du lieu (salle de réunion, restaurant, hall d'accueil,...). C'est ainsi, qu'il sera possible de moduler la réverbération, la diffusion et/ou l'absorption de l'onde sonore.

Oberflex pour le retail

Les 10 bonnes raisons d'utiliser les panneaux Oberflex pour l'agencement de magasins

269 tonnes de CO2 absorbé

Contribution carbone

Ober & EcoTree, un partenariat vertueux pour l'environnement.

Oberflex vous accompagne

Oberflex accompagne les Architectes, Acousticiens, Agenceurs, pour créer les conditions de réussite optimale de chaque projet en mettant à leur disposition les ressources techniques de son Service Clients.

Staron® solid surface

La solid surface Staron®, est un matériau massif, homogène et non poreux, qui se travaille comme le bois.

Chêne crack et Chêne fleuri

Panneaux en Chêne à fortes singularités.

Nouveau catalogue Obersound

Découvrez l’ensemble des solutions acoustiques Obersound à travers le catalogue, un outil de travail indispensable pour les acousticiens, architectes et prescripteurs.

50 ans d'innovations

C’est en 1968 que Oberflex invente le premier panneau stratifié en bois véritable, né de la rencontre d’un savoir-faire traditionnel d'assemblage des bois, et de la mise au point de la stratification à chaud, qui confère à la surface du bois une résistance exceptionnelle.