Sablés unfinished

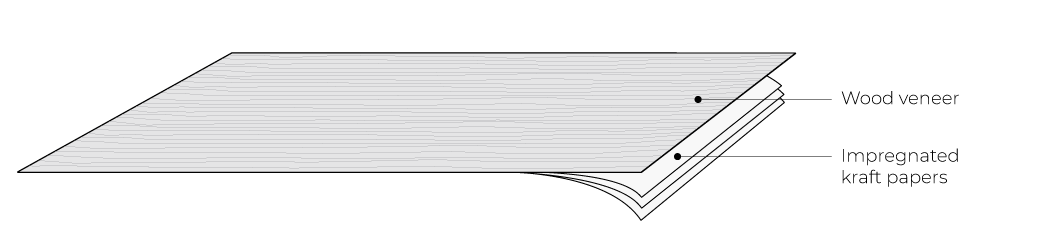

Real wood veneer sheet unfinished, made of +/- 6/10e wood textured veneer on a laminated substrate. Advantage : high resistance to impact. Sanded texture. Unfinished (has to be varnished, oiled...). 9 natural wood species available.

Products

Applications

Wall

Ceilings

Doors

Furniture

Available products for this surface

Ready-to-bond Sablés unfinished laminate

Panober bonded panels

Edge bandings