Metal d'Oberflex

Metal by Oberflex is a decorative metal surface offering that includes the Pure Paper Metal and Metapal collections.

The aluminum surfaces are brushed, matt, rough rolled or mirror polished. Copper, stainless steel, pewter, brass, bronze or gunmetal tones are available in smooth surfaces or enriched with geometric or organic 3D patterns.

Products

Skin

Skin boasts a smooth surface whose simplicity brings out the colors. The matching finishes reveal the depth of the material, taking on a delicate tone with light.

Matt & scratch-resistant

Metal laminates with an extra-matt finish and enhanced surface resistance, particularly suitable for more intensive use.

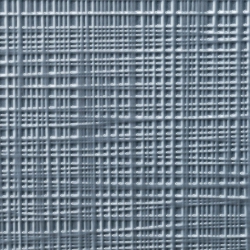

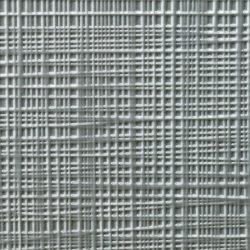

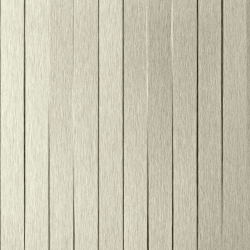

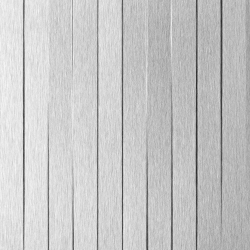

Fibra

Till

Skarp

Drapa

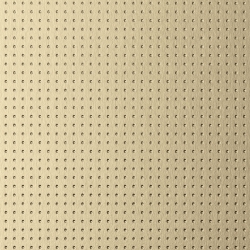

Dots

Design by Patrick Norguet.

An unvarying thread vanishes, giving way to a delicate constellation; a multitude of hollow points exhibiting their decorative grace and elegant serenity.

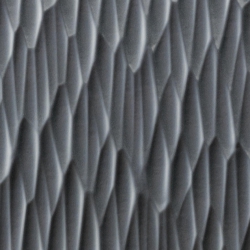

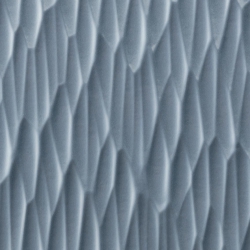

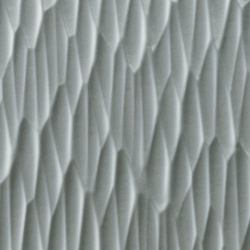

Sticks

Design by Patrick Norguet.

Fish scales or impossible perspectives, visual styles intermingle to the delight of the eyes. The pattern inspired by natural structures strikes balance in repetition.

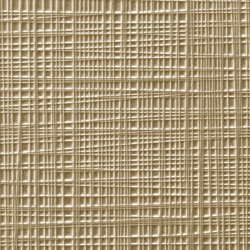

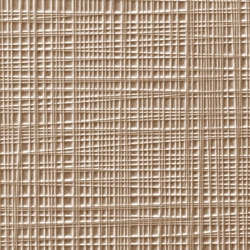

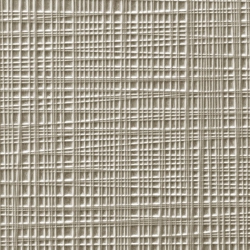

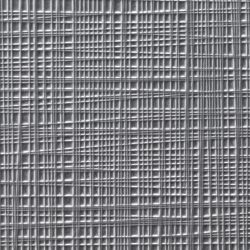

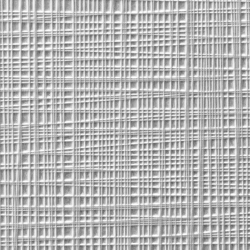

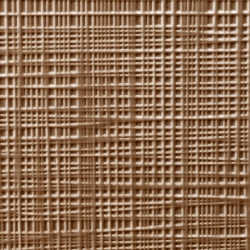

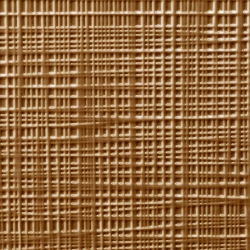

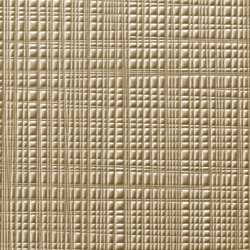

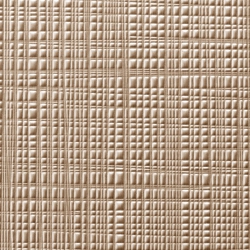

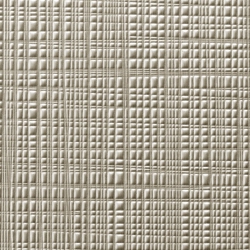

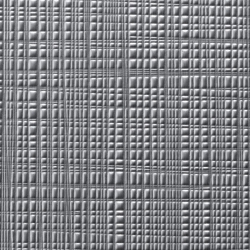

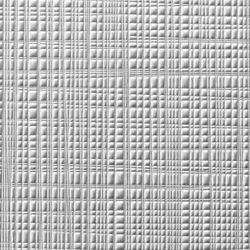

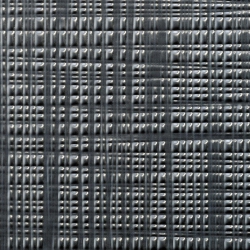

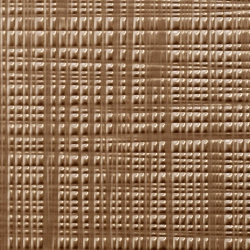

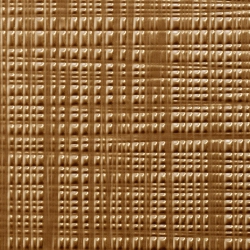

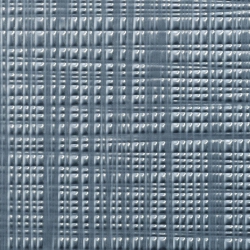

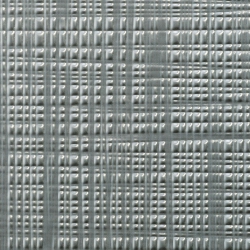

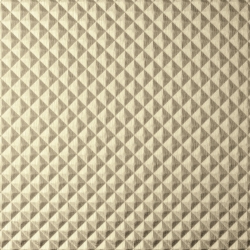

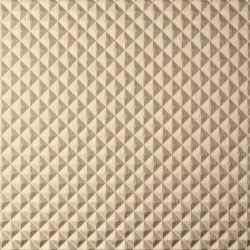

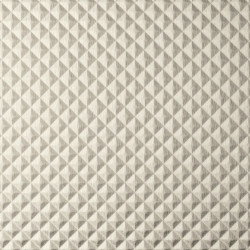

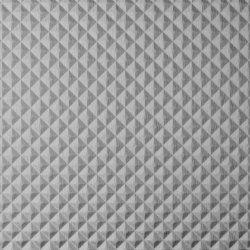

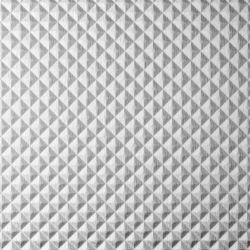

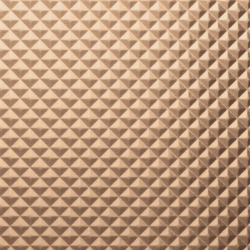

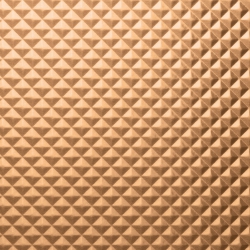

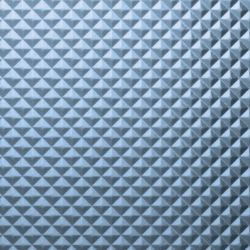

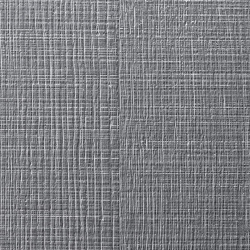

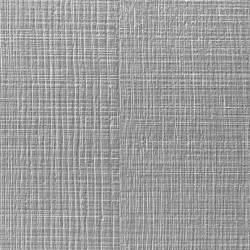

Net

Design by Patrick Norguet.

Small geometric shapes like shortened pyramids occur in a repetitive pattern. A background of intersecting diagonal lines draws a net with a soothingly regular pattern.

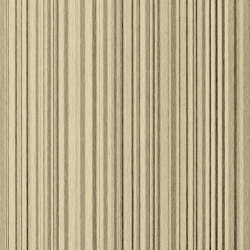

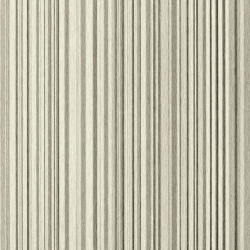

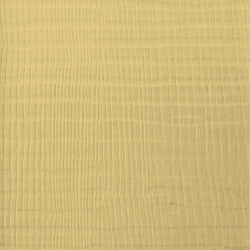

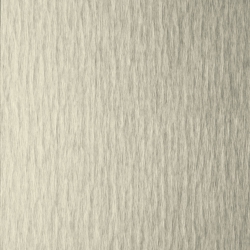

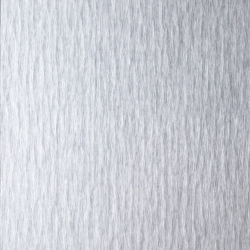

Lines

Design by Patrick Norguet.

Transversal compression and random angles and widths create an uneven and disconcerting pattern. Like natural structures, these unpredictable lines form a fascinating relief.

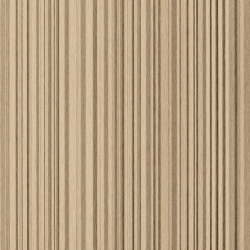

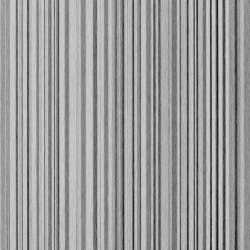

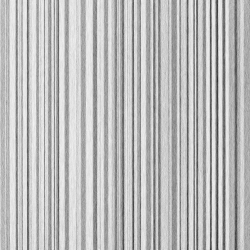

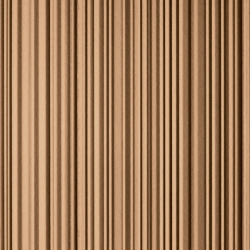

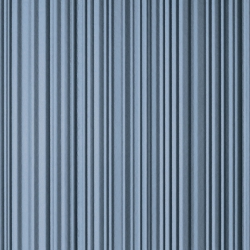

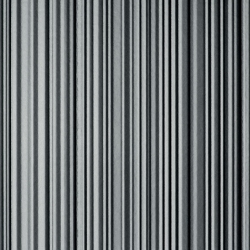

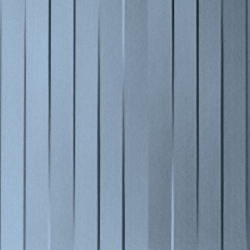

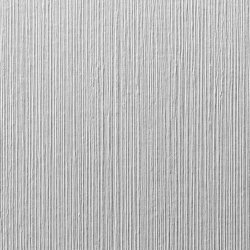

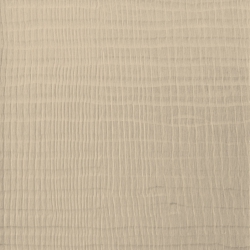

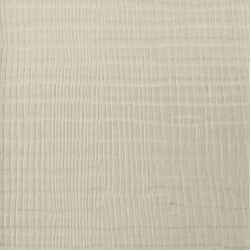

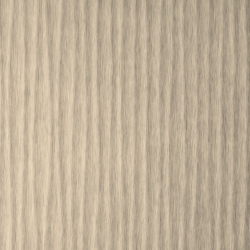

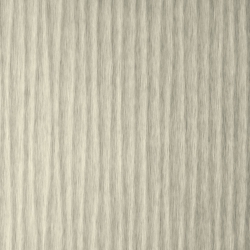

Stripes

Design by Patrick Norguet.

A series of twisting stripes create the illusion of vibration. Surprises and movements bring the verticality of these eroded strata to life.

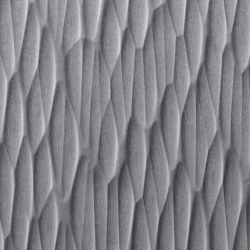

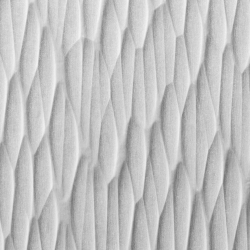

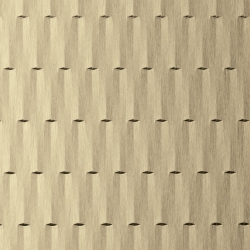

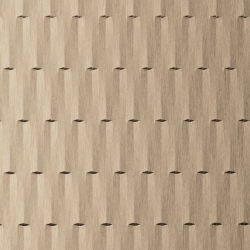

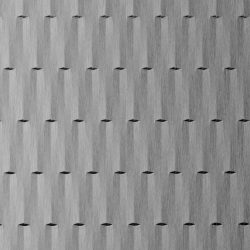

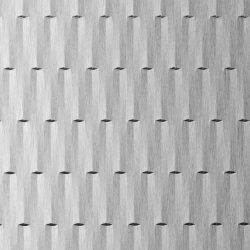

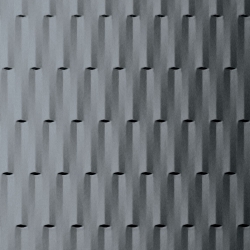

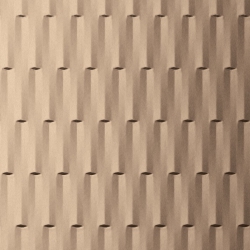

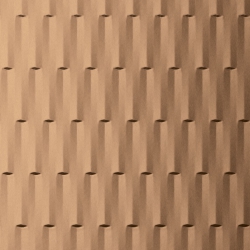

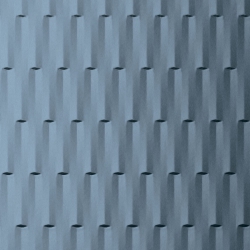

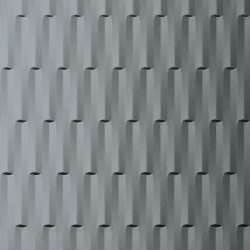

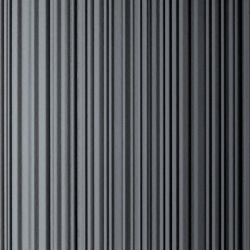

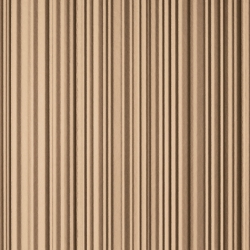

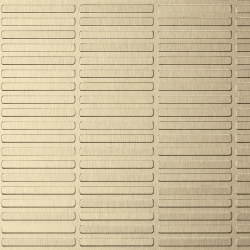

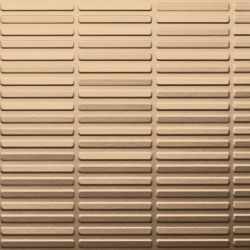

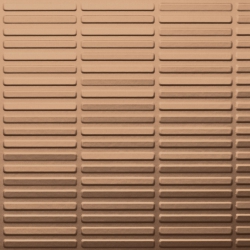

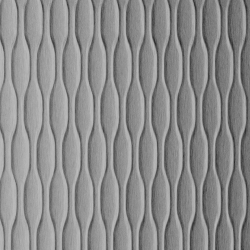

Tabs

Design by Patrick Norguet.

Whether assuming the form of louvers or facings, tabs positioned in different angles and depths create rhythmic play and reflections, generating a vibrant surface.

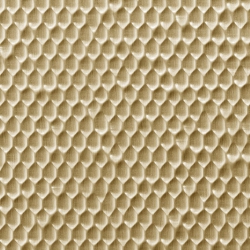

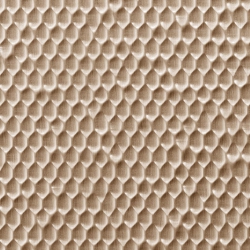

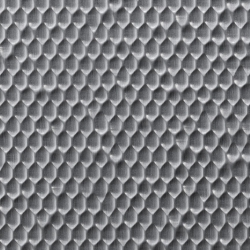

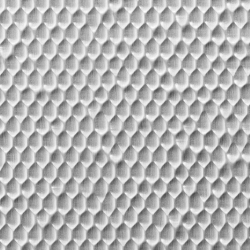

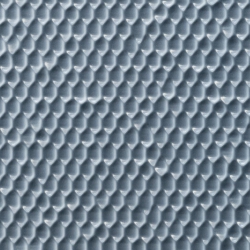

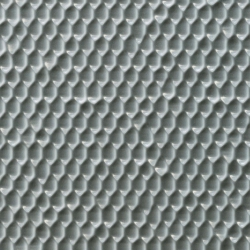

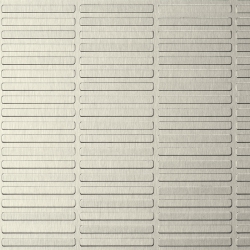

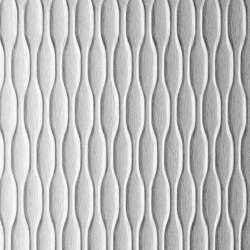

Mesh

Design by Patrick Norguet

Inspired by alveoli, this rhythmic and comforting geometric mesh infinitely stretches like prints on fabric. Graphic design is settling in the heart of interiors.