Oberswing Natur

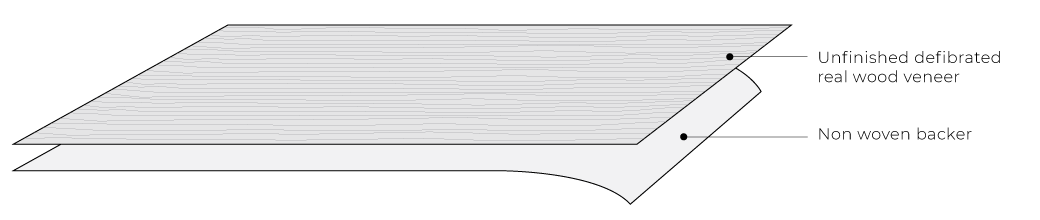

Extra flexible wood veneers for curves and tight bending radius up to 10 mm.

Products

Applications

Wall

Ceilings

Doors

Furniture