Textured Wood collection

Gouged, clawed, hammered veneers. 9 textures proposed in nuances of white, black and grey. Oberflex finish.

Fire reaction

Impact resistance

Abrasion resistance

Scratch resistance

No attack by common-type products

Light resistance

Easy maintenance

Products

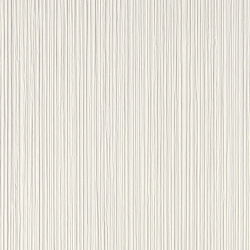

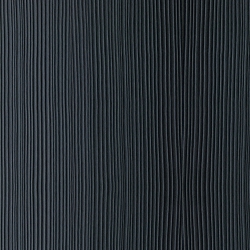

Fibra Wood

New collection

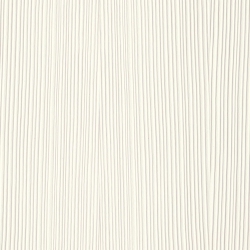

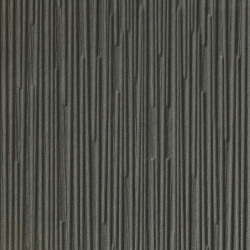

Till Wood

New collection

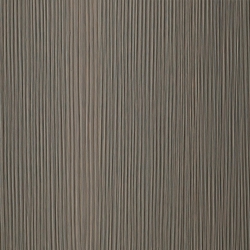

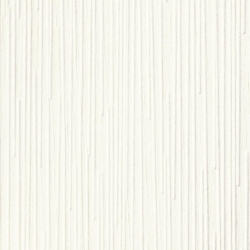

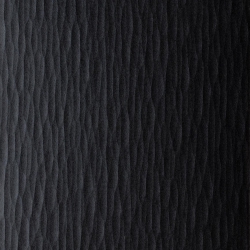

Clawed Wood

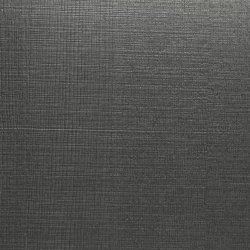

Sablé Wood

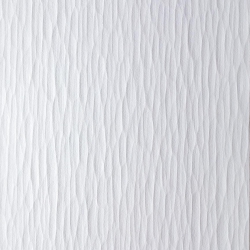

Cleft Wood

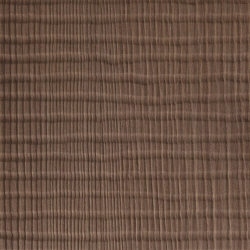

Sawn Wood

Hammered Wood

Gouged Wood

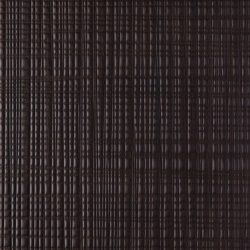

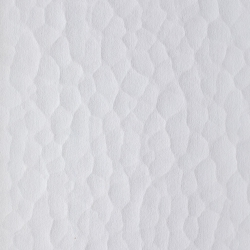

Gator Wood

Sea Wood

Applications

Wall

Ceilings

Doors

Furniture

Available products for this surface

Ready-to-bond Textured Wood laminates

Panober bonded panels

Edge bandings