Acoustic

Based on their technical characteristics (size, thickness, shape, density, etc.), perforation rate, and how they are built, all Obersound acoustic panel models offer a specific sound absorption performance. Other factors, such as the residual space between the back of the panel and the primary substrate, the characteristics of the black fleece and the rock wool used, also affect panels’ acoustic performance once installed.

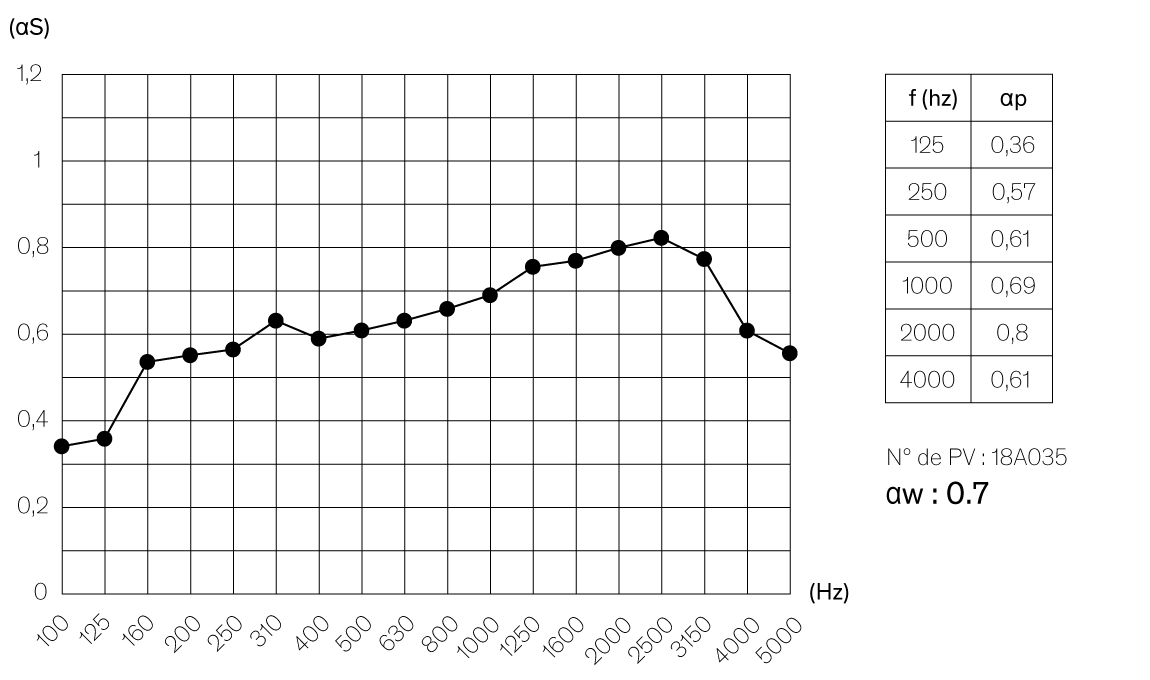

Measuring the absorption performance of an Obersound perforation model consists in placing 15 m² of panels in a reverberation chamber and measuring, according to the frequencies (100 Htz and 5000 Htz), the proportion of reflected waves to deduce the proportion of absorbed waves.

The result is a curve showing the absorption coefficient, expressed in Alpha sabine αS, which varies according to the frequencies in Hz (bass to treble) and an average expressed in αw ranging between 0 and 1. The panel’s perforation percentage is an additional indicator.

Oberflex’s design office oversees all the acoustic tests. Test reports and briefs are available upon request. On a case by case basis, our modeling software also allows us to refine the performance of a model once installed, taking into account the overall context of the project.

All these characteristics are governed by the NF EN ISO 354 (2004) standard: measuring sound absorption inside a reverberation chamber.